Leather goods

DIRECTION PRODUCT DESIGN CRAFTSMANSHIP BRANDING

Concept & mission

The purpose of creating unique and original leather goods was to pursue a product design that used natural materials in an all new way. My intentions were to think outside the box, compose products using minimal shapes and styles, and create a product that influences the user in a positive way. By building a wide range of products for Flume Leather Company, I was able to do just that.

project details

Each product is designed with the principles found in nature. Major aspects are built in proportions of three, each focal point is placed using rules of thirds, and in an effort to design outside of the box, each product features the asymmetrical natural cut curve. These leather goods are built based on the theme of a natural waterway, and its handmade process is devoted to protecting those natural waterways. Along with only using the best natural materials sourced locally, the leather tanning, dying, and treating process avoids the need to wash any harsh chemicals down the drain.

Minimal

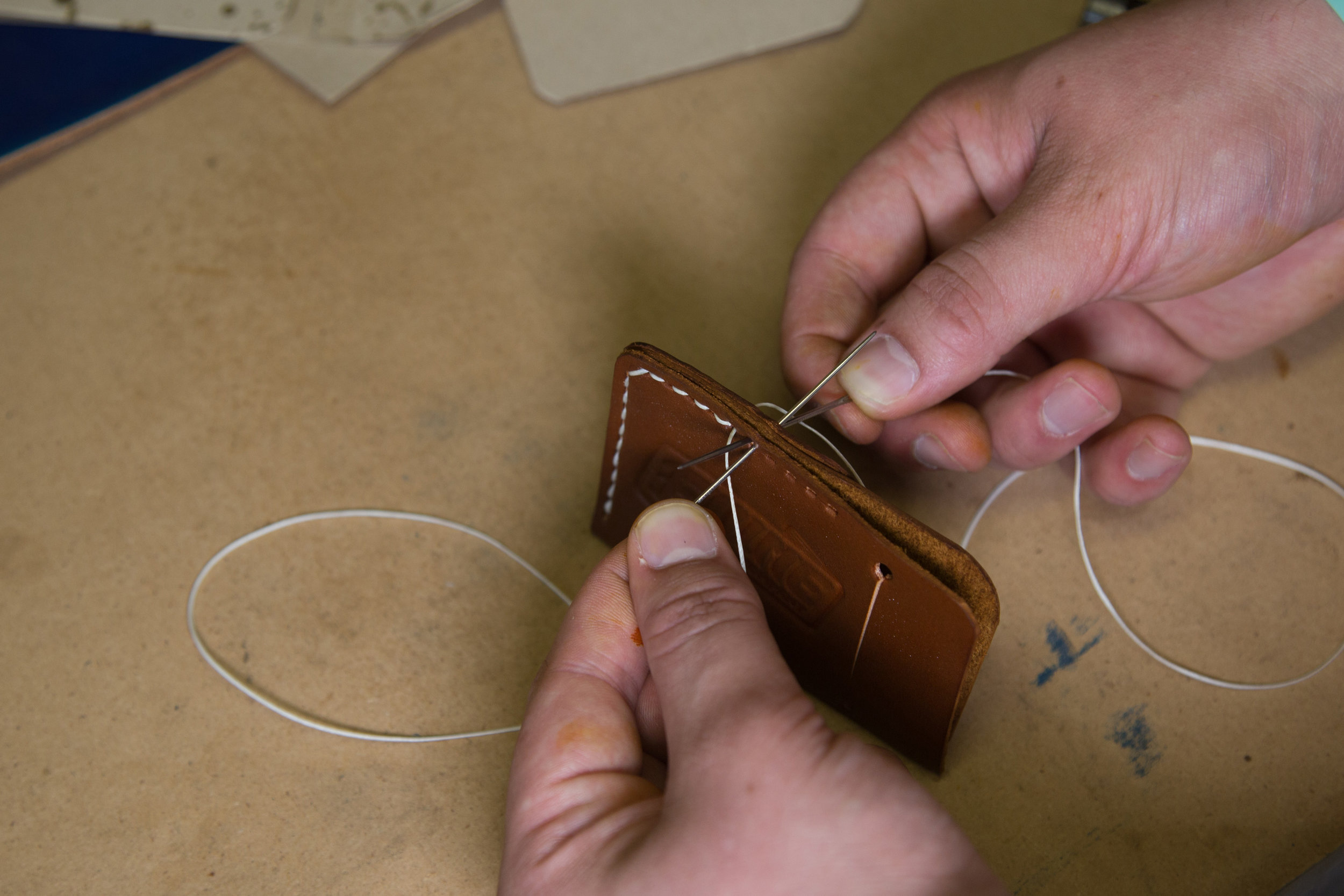

The thought and process of making leather goods have modeled my designs to be as minimal as possible without sacrificing function or quality. Completely rethinking the wallet yielded new ways to carry cash, cards, and receipts, all by creating a wrapped piece of leather with a few cuts, punches and stitches. The end goal for every product is to create an ergonomic and user friendly piece that gets better with time. This kind of craft is made by sketching, creating templates, and hand cutting each piece of leather straight from the vegetable tanned hide.

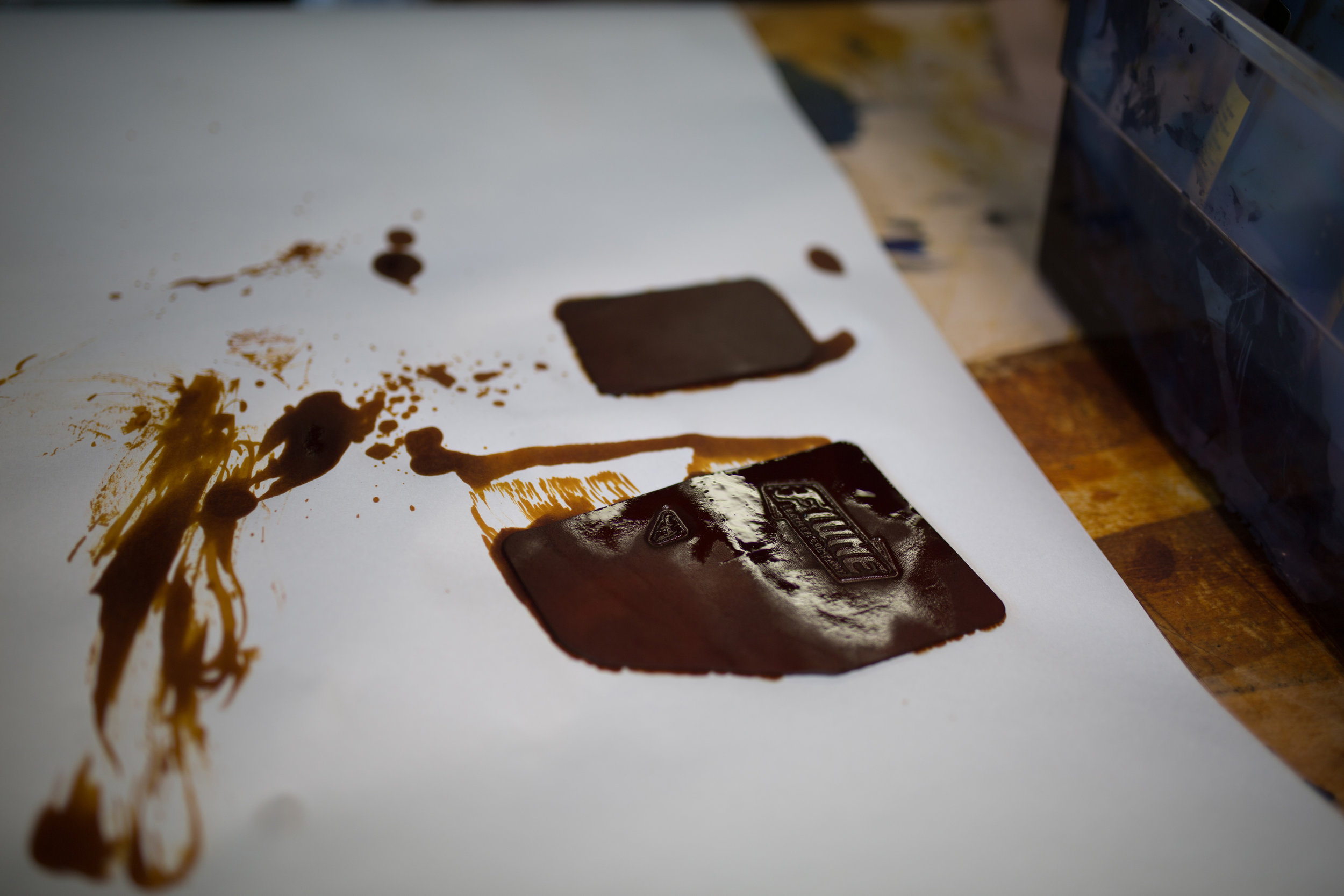

Process

Leather naturally has some strange tendencies, and after many trials I learned a few tricks to bringing out the best in each square inch of the hide. After hand trimming each piece directly from the hide, the corners are trimmed with an arched rounding tool and arbor press, and then soaked in water to make the leather soft, susceptible to impression, and primed for dying an even coat of color.

A smooth finish

Even with a messy process, limited tools, and just enough budget to acquire the best materials, I've been able to refine the sustainable coloring process, hand-punching and stitching process, and finish each piece with a clean burnished edge. Although being a full time student with an internship and another part time job, I have been able to create the entire making process as well as brand a small leather goods company and online store that fosters my love for product design. After a year of launching products, seasonal campaigns, and product collaborations with other designers and studios, I have built a solid line of dependable products.